Welcome to the future of facility management! As a dedicated facility manager, you know that staying ahead of the curve is key to success. In the digital age, embracing automation and AI is no longer a luxury – it's a necessity. Let's explore how integrating advanced technologies like CMMS platforms, IoT sensors, and robots can revolutionize your facility management practices and take them to new heights.

Embrace the Power of CMMS Platforms

Streamlined Workflows: Bid farewell to manual processes and paperwork. With a robust CMMS platform, you can digitize work orders, track maintenance schedules, and manage assets effortlessly. Save time and stay organized.

Data-Driven Insights: CMMS platforms offer valuable data insights to make informed decisions. Leverage real-time reports and trends to optimize maintenance strategies and boost efficiency.

Optimized Resource Allocation: Allocate resources smartly with predictive maintenance capabilities. Identify potential issues before they escalate, saving costs and minimizing downtime.

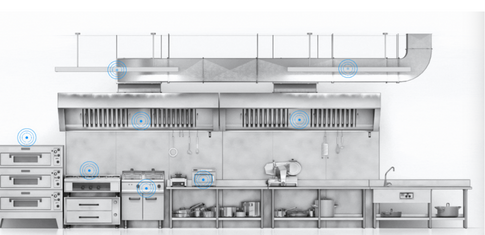

Harness the Potential of IoT Sensors

Real-Time Monitoring: Equip your facility with IoT sensors to monitor critical systems in real-time. You'll have a comprehensive view of your facility's performance from temperature and humidity to energy usage.

Proactive Maintenance: Detect anomalies early and address them proactively. IoT sensors can identify equipment issues, preventing breakdowns and costly repairs.

Enhanced Safety: Create a safer environment with IoT sensors that monitor hazardous areas and alert your team to potential risks. Safety first, always!

Embrace the Robot Revolution

Efficient Cleaning and Maintenance: Robots can take over repetitive tasks like cleaning and maintenance, freeing up your team for more strategic projects.

24/7 Operations: Some robots can work around the clock, ensuring continuous monitoring and efficient operations, even during off-hours.

Augmented Workforce: Robots and humans make a powerful team. Embrace robots as valuable allies that complement your team's skills and enhance productivity.

Overcoming Challenges and Embracing Change

Training and Adoption: Empower your team with training on the new technologies. Address any concerns they might have and highlight the benefits of automation and AI.

Data Security and Integration: Ensure robust data security protocols when implementing new technologies. Also, focus on seamless integration with your existing systems for smooth operations.

Flexibility and Scalability: Choose technologies that can adapt to your facility's evolving needs and accommodate future growth.

Conclusion

The digital age presents a sea of opportunities for facility managers to excel. By embracing automation and AI through CMMS platforms, IoT sensors, and robots, you'll not only streamline operations but also enhance efficiency, safety, and resource allocation. Embrace the future with open arms, and witness your facility management practices soar to unprecedented heights.

INDUSTRY INSIGHT

What's Happening at Ecotrak

Heraclitus, an ancient Greek philosopher, is attributed the oft-quoted “change is the only constant in life.”

For many in facilities management, that insight has never felt more relevant. Facilities managers and operators are facing new challenges and economic forces, and change seems to be the only certain thing the industry can rely on.

One thing you can be sure of is that your restaurant will continue to need to maintain and repair equipment to stay in business. However, you may need to revisit your “business as usual” approach to labor, equipment, and managing facilities.

Operators are facing major challenges in two areas: labor (both in-house and with vendors) and supply chain issues (both for new equipment and for parts). Here, we’ll cover tips to help manage facilities and construction during periods of uncertainty. Adopting a new Computerized Maintenance Management Systems (CMMS) facility strategy may help you find new solutions for labor and facilities management challenges.

Uncertainty #1: Labor Challenges

As most operators will tell you, demand is trending high. Organizations are facing an increase in sales concurrent with a general decrease in available labor. Facility managers are facing higher turnover, reduced availability, and potentially less experienced staff — both internally and with vendors.

Labor Within Your Organization

Much of the labor crunch is affecting entry-level roles. For example, as a restaurant operator you may not have enough servers or cooks to fill out the everyday schedule. Or, you may have noticed a decrease in the experience levels of potential employees, as people trained in the industry move to different verticals. These challenges can take from your managers time, forcing them to spend their time focused on day-to-day functions of the facility rather than managing strategically at a high level.

When it comes to managing facilities, busy operators need a tool to help them efficiently manage maintenance of equipment. Facilities management is a high priority, your operators need to be able to rely on their partnerships with service providers, and yet your management may no longer have the time to call, vet, and follow up with vendors.

Your Service Providers’ Labor Challenges

Service providers are facing the same labor shortage issues that facility managers are, particularly as technician demographics indicate an aging workforce without the same number of new workers. With labor as a challenge, many service providers may be resorting to the 80/20 rule (80% of profit is coming from 20% of customers). To cope with labor shortages, some vendors may not prioritize new customers or existing clients that aren’t in the top 20% of their business.

Addressing Labor Challenges with a Facilities Management Solution and Strong Service Provider Relationships

First, if your facility managers are spread too thin, a CMMS can empower your team to tackle more than ever. A CMMS solution can streamline connecting with service providers and automatically provide all the details that they’ll need (make, model number, maintenance history, etc). Your team can tackle challenges successfully, reduce time on the phone, and increase repair accuracy. They can also use the CMMS platform to track costs, invoice status, and spending in real-time.

Second, a CMMS platform can provide not only streamlined communication, but also help you strengthen your service provider partnerships as well. A CMMS solution like Ecotrak has long-standing relationships with service providers that can help bridge a new relationship between your business and vendors.Ecotrak maintains a vetted group of vendors on our system that each have been invited by a fellow industry professional. Ecotrak also now offers a service provider directly that provides access to vendor names. The directory includes performance indicators, such as time to accept, time to arrive, time to complete, and cost of invoice, allowing you to enter a relationship with a new service provider based on measurable outcomes.

Uncertainty #2: Supply Chain Disruptions For Equipment and Parts

After a few years of unprecedented global complexities, the supply chain for facilities is also facing new challenges in two areas in particular: limitations on equipment manufacturing capability and a shortage of parts.

Delays in Equipment Manufacturing & Shortage of Parts

Global challenges to the supply chain, the rising cost of raw materials, and complicated shipping logistics have roiled the facility equipment industry. Many major manufacturers now are facing a timeline of at least 18 months for production of new equipment.

For an operator, this delayed timeline is changing the standard calculation of repair vs replace. Maybe you planned to replace ovens when they hit 10 years old. Unless your organization is proactively planning equipment orders, you may face major delays with your planned timeline and have to pour money into an asset that should have been already off your books.

For similar reasons, facility operators and service providers are also finding a shortage of parts for equipment. Without planning in advance for replacements, you may lose the functionality of a critical piece of equipment for a relatively small part.

Generally, there aren’t a lot of proactive programs to plan effectively to manage your asset base. But in today’s economy and labor market, it will be difficult for your facility to be efficient and effective without functioning equipment.

Asset-First Philosophy to Face Supply Chain Challenges

To address some of these challenges, a CMMS solution like Ecotrak can facilitate an asset-first philosophy to your asset management program.

What might an asset-first philosophy look like in facilities management?

1. Understanding your most vital pieces of equipment

2. Identifying if there is a common failure or replacement part you may want to stock for your facility “crash kits”

3. Tracking the retirement age of equipment so you can plan very far head for proactive replacement

4. Creating a strong maintenance program to keep your priority equipment running

Let’s go over each of these ideas in detail.

#1 - Understanding your most vital pieces of equipment

Many facilities in today’s economy don’t have redundancy built into them. Think about the most critical piece of equipment that you have — if it goes offline, can you deliver to your customers?

A CMMS can help you track data about your vital equipment. When your asset inventory is cataloged in your CMMS, you have the make, model, serial number, and any warranties centralized on one system. A work order runs through all related data points to check for warranty, and information is automatically sent to the service provider with the work order (particularly helpful if service is also experiencing high turnover or has new employees).

#2 - Identifying if there is a common failure or replacement part you may want to stock for your facility “crash kits”

You don’t want to lose sales because you are waiting for a $20 part for your most critical piece of equipment.

A solution like Ecotrak can help you identify the most common failed parts for your equipment (across your facilities or, with advanced systems, aggregated across a larger data set). When a service provider invoices, they log any parts they replaced. With this data, you can create crash kits for your facilities that contain the most critical, core component parts for your vital equipment.

Now that you’ve supplied your own parts, you can focus on the service provider relationship (and also potentially cut down on service overhead).

#3 - Tracking the retirement age of equipment so you can plan very far ahead for proactive replacement

To address manufacturing delays, operators may need to place a higher emphasis on proactive equipment maintenance. It can be beneficial to pull reports on which equipment is outside useful life, where repair and maintenance dollars are going, and the level of effectiveness of your contracted maintenance. With a consolidated list for your financial planning, facility leadership can make strategic decisions on a long-term, proactive timeline.

#4 - Creating a strong maintenance program to keep your priority equipment running

Your CMMS can be used to track the age of your equipment and assets that have depreciated based on industry standards or your company’s accounting practices. The machine learning of a CMMS solution can even help you build analytical models for when your equipment needs to be repaired or replaced. Prioritizing maintenance can help you optimize the life cycle and input cost over your equipment lifetime.

If uncertainties shift further and sales decline, generally the first thing operators pull back on the maintenance program, grabbing money out of the Repairs & Maintenance (R&M) line because it connects straight to the bottom line. However, there is a repercussion for altering an important part of the budget. You may start to see earlier equipment failures, or higher dollars to perform essential maintenance.

If you do need to limit maintenance dollars, you should measure the effects to understand how it may catch up to the business. Will you create a higher capital budget in two years? Can you measure the effectiveness of your R&M in different locations that cut back differently? Understanding these questions can help inform your overall business strategy.

Your Business Can Adapt to Uncertain Times

Your facilities business may be undergoing new tests, but you have the tools and experience to make changes to grow and thrive. With an understanding of industry trends, tools like a robust CMMS, and the expertise of your team, you can face any new challenge coming your way.

Ecotrak Facility Management is the most comprehensive cloud based software platform that manages all key performance indicators in the facilities profession. The solution offers an asset management program that produces work orders, tracks and executes warranties, and has a robust reporting platform. Sign up for a personalized demo of Ecotrak.

INDUSTRY INSIGHT

What's Happening at Ecotrak

Facility and asset management requires keeping track of multiple moving pieces. Whether you’re tracking work orders, vendors, or invoices, you and your team need to create systems that match your business needs.

Developing a network of reliable service providers is a key part of keeping your operations running smoothly. While service providers may not work for your business as employees, successful partnerships minimize interruptions to your equipment and facilities with timely repairs and proactive maintenance.

A reliable, high-quality service provider network is essential for your business, and yet, devoting the time to research and vet service providers can feel like a daunting task.

You’re not alone in your search for the right service provider for your business. Here, we’ll go over how you can approach the task, what you should be looking for in a service provider, and the places and tools you can use to make the process easier.

What to Look for in Your Service Provider

If you were looking to find a new food vendor for your facility, you would take your time in the research phase before signing a contract. You’d ask questions about their sourcing, standards, systems, and other details like payment terms.

The same care and concern should go for your service provider. You’re not just looking for any service provider; you’re looking for a partner who can deliver for your business and your needs. As you start your search, it’s important to keep certain qualities in mind.

Experience & Stability

Just as you draw from your experience to determine your facility management strategy, your service provider should also have a secure foundation of industry experience. Don’t be afraid to ask for details of a potential service provider to understand how “mature” their business is.

Consider starting with questions like:

● How long have you been in business?

● How many clients do you have? (Are any of them local or similar to my business?)

● What is your training and experience?

● What is the training and experience of your employees?

Relevant Certifications

Depending on the exact service, a potential service provider may be required (or simply encouraged) to have certain certifications. Consider asking any service provider about their trade background requirements and any relevant professional certifications.

In addition, if you use technology tools such as facility and asset management software, your service provider should already have the ability to use your system or be willing to undergo training to get up to speed.

Responsiveness and Accessibility

Whether you need to plan scheduled maintenance or last-minute repairs, accessibility is an important trait to look for in a service provider. How quickly your service provider can schedule services is a critical factor in how they will work with your business. Take the time to communicate your expectations at the beginning of the relationship, so you can decide whether potential service providers will be available and accountable when you need them the most.

In addition, don’t want to wait until a critical piece of equipment is broken to figure out who to contact in an emergency. Discuss upfront what methods work best for everyone: phone calls, texts, app messages, emails? How does your facility staff prefer to communicate, and how does the service vendor communicate? Agreeing on these details ahead of time can help you manage expectations and keep both parties happy.

Quality of Work

Ultimately, engaging with a service provider is an investment in your facilities. You want a high quality of work that you can trust. Even though you may sometimes need a service provider to respond urgently, you also don’t want to compromise the quality of work. Your service provider should balance accommodating your immediate needs and meeting expectations.

Courteous & Thorough Communication

Throughout your vetting process, your potential service provider’s communication style can indicate a lot about their customer service.

Both you and the service provider should devote time to developing your relationship, even before any contract is signed or work is completed. While a service provider will inevitably have other clients, they should have the capacity to communicate thoroughly with you as a client.

How to Find the Right Service Provider for Your Next Project

There are many ways to help you find the right talent for the job. You may need to use a mix of different methods to find the partners you need, but investing this effort over time can pay dividends for your facilities.

Online Search & Reviews

One of the most common and immediate ways you can explore for a new service provider is through an online search. You can find names of various service providers, contact information, and even reviews about services.

While this method is relatively easy, it comes with its challenges. Searching for something like “plumber near me” can lead to an almost overwhelming amount of information.

Reviews can be a helpful tool in your search, allowing you to learn about experiences other business owners have had with a certain service provider. However, reviews don’t tell the whole picture. Some quality service providers may not actively prioritize reviews, leaving them as an unknown factor. Other times, reviews may range widely, leaving you unsure about the quality of a vendor.

An online search can provide a lot of information, but you may be left with more questions than answers. Ultimately, the results of an online search may not be extremely well-vetted.

Reviewing Service Provider Websites

If you want to go one step further than online search and reviews, examining service provider websites can tell you a lot about their business. Take a close look at their online presence, including any testimonials, helpful resources, or blogs. An active, thoughtful online presence can indicate that they prioritize communication with their clients — a trait that you want in your service partner.

Word of Mouth

Asking your peers about local service providers can be another great strategy. You can hear from businesses that may be facing similar challenges to your facilities. However, if you aren’t connected locally with other business owners or some businesses are hesitant to share their experiences, you may need to look elsewhere.

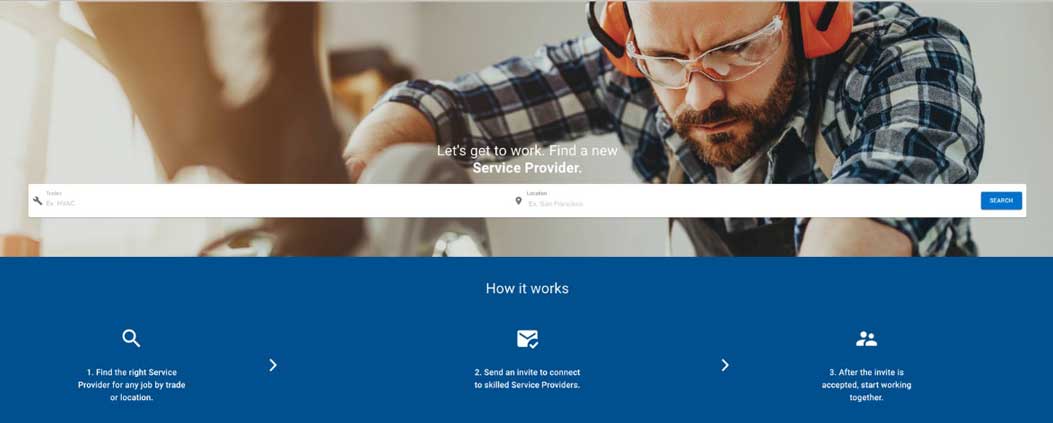

Service Provider Directory

Using a tool like a service provider directory can be one of the most effective ways to find your next service provider. These directories leverage word of mouth, relying on service providers that work with real facilities. Because the directory is managed, service providers are also typically more vetted than a generalized online search.

For example, Ecotrak maintains a nationwide service provider network for various trades. Available to Ecotrak customers, this resource connects facility management professionals with service providers that work in their region.

Your business can benefit from direct communication with service providers within the software. These service provider professionals are already trained and up to speed with how to use our facility management software system, allowing you to take advantage of streamlined requests that include equipment details, historical asset information, and even photos.

Finally, with a service provider directory, you can rely on quality indicators like the Ecotrak Certified Vendor Badge, granted to trusted vendors who have completed Service Provider Training.

Finding Service Provider Success

Creating a network of reliable, high-quality service providers takes an investment of time and energy. However, with the right approach and tools at hand, you can develop valuable relationships that support healthy business operations.

Request a personalized demo of Ecotrak today to see how the leading Facility and Asset Management Software can help you find, organize, and leverage quality service providers.

Ecotrak’s full-service provider directory will be launching in July of 2022!

INDUSTRY INSIGHT

What's Happening at Ecotrak

There are myriad ways the COVID pandemic has impacted and disrupted us all, which has resulted in the unusual holding pattern in which we currently find ourselves. We know things will eventually return to quote-unquote “normal”. We know it will be a new normal. We know that how you choose to position yourself during this time could make the difference between soaring high upon the industry’s recovery or being left behind.

Restaurants have been hit particularly hard. The reduced workforce is wreaking havoc, and it’s incredibly difficult to rely on vendors to be there when you need them, and the only thing you can count on these days, it seems, is the continued need for repair and maintenance of equipment.

Thankfully, technology can help. As we’ve all been forced to think outside the box and come up with new strategies and processes on how to accomplish day-to-day activities, your CMMS facility strategy also needs to adapt. But what should it look like in a post-pandemic world, and how can it help position you for success?

Managing and Planning

When the COVID-19 pandemic descended upon us so quickly in early 2020, nearly every restaurant was forced to part ways with some percentage of its workforce. Hiring back has been an enormous challenge, particularly as we continue to navigate consistently inconsistent rises and falls in COVID variants and their accompanying protocols and restrictions. Since many veteran restaurant workers have now transitioned to other industries, there is an inexperienced pool of applicants. The numbers are staggering:

- According to the Bureau of Labor Statistics, as of late 2021, restaurants were trying to fill 1.7 million jobs.

- 28% of operators believe it will take between 7 and 12 months to return to normal.

This is where a good CMMS platform can help.

In managing workload, a good CMMS allows you to ramp up quickly. It allows you to be in tune with your locations without having to be on-site. It maintains clear-cut processes for the benefit of veteran and new employees alike, keeping everyone on the same page and training much easier.

In the restaurant industry, things will go wrong; equipment will fail, facilities will break. A CMMS eliminates frantic questions of who should be called, where is the vendor’s contact info, how much must be allotted for that repair. By removing such concerns, your team can instead focus on running a successful restaurant and adapting to the new normal.

Another thing about this new, younger workforce: They are more “plugged-in” than any generation before. They’ve grown up surrounded by technology, and expect it to inform, guide, and assist them in everything they do. Their expectations at work will be no different, which is why you’ll want to increase operational efficiency and put actionable data and analytics at their fingertips. Train them, empower them, then allow them to focus on the guest experience that will be so vital in determining which restaurants continue to move forward.

Real-time visibility

If we are to effectively manage this predominantly-new workforce, we’ll need more of a reliance on CMMS than ever. Heading into the pandemic, most restaurant concerns fell under the heading of penny-pinching, looking to see where they could trim the fat. These days, maintaining profits continues to be a concern. It has also been compounded by workforce worries, suddenly unavailable service providers, and other issues.

Let’s say it’s the dead of summer, 105 degrees outside, and your HVAC goes out. Now your guests are essentially sitting in a sauna, your kitchen is vulnerable, and you’re in danger of losing a day of revenue. It is crucial that whoever is addressing the problem is empowered to get ahold of the proper service provider, get them the information they need to come out, and have all the details they’ll need on the unit – its age, model number, maintenance history, and so on.

Questions abound, and you’ll have the answers: Is it time to repair or replace? What is the effectiveness of your contracted maintenance? Where are repair and maintenance dollars going, and why? With a CMMS like Ecotrak, a desktop interface and app allows you to streamline communication, reduce time on the phone, increase accuracy and get it all to the right vendor every time.

At a moment when you need streamlined facilities management to counter a reduced workforce, it’s more important than ever that you get things right the first time. A first-time fix helps minimize downtime, maintain that all-important relationship with your guests, and allow others to stay focused on front-of-house concerns. The next time they need a plumber, an electrician, or anyone else, all they need to do is open the app and with a few swipes, they can get the information and approvals they need to resolve a situation.

The CMMS platform then provides invoice statuses in real-time, so it’s simple to track costs, monitor spending, and ensure that your service provider has been paid. And you can bet that the service provider will remember your organization and promptness, so the next time that phone rings, they’ll pick up quickly.

Using data, you can reduce your repair and maintenance spending. You can improve vendor relations and sidestep equipment downtime. You can streamline your facilities management and navigate this tricky time of reduced workforces.

Responding to a crisis is one thing; preventing it is far better. A good CMMS solution is akin to having a psychic on your payroll, as it uses machine learning to analyze your data and automate the building of analytical models that predict when, where, and how soon your equipment will need to be repaired or replaced.

As we move past this pandemic, and the volume that comes back, your structure will be amplified. In other words, if you have a good structure and a solid CMMS solution in place and are well-deployed, you’ll be able to flex those strengths. If you don’t, your weaknesses will inevitably become your Achilles’ heel, leading to more wasted hours, wasted money, and wasted effort. Reducing spending and managing maintenance is the common goal of every restauranteur, and a good CMMS solution can position you to make sure that when we finally emerge from all this, you’ll be in control.

INDUSTRY INSIGHT

What's Happening at Ecotrak

It happens at home, just like it happens on the job. You take the time to research appliances, shop around for the best rate, set up your kitchen just the way you like — all in time for something to break down without warning. But while at home you might be able to scrape by without a stovetop for a few days, when it comes to work, inability to function means inability to serve, which means inability to open your doors.

Asset lifecycle management brings predictability to the unpredictable. It allows you to maximize your investment, minimize time spent grappling with adversity, and utilizes the latest in metrics and data analysis to help you learn how you can get even more value out of your appliances.

If you have a good asset lifecycle management plan in place, the three factors listed below are friendly, not fearsome. If you don’t, well, you’re operating like a chef with both hands tied behind his back.

Knowing what the future holds

Every asset has a natural, four-stage lifecycle: Planning, Procurement, Operation/Maintenance and Disposal. Whether your restaurant’s kitchen is shiny and new, or you’re acquiring equipment that already has a few years on the odometer, each item is at some stage of this lifecycle.

If you’re in the early days of a small operation, you might be able to keep track in your head of what’s new, what’s old, and what’s being held together with duct tape. But when your business becomes multiple locations, with multiple kitchens, and you’re making significant investments in ovens, deep fryers, refrigeration, beverage dispensers and more, it can very quickly overwhelm any facilities management team.

A smart business has the foresight to consider the entire lifecycle before even moving beyond the planning phase. As you’re researching manufactures and considering which model is right for your needs, you should also be analyzing likely maintenance costs, the average lifespan of the asset, and what kind of daily wear-and-tear it will endure in your kitchen. As you move into procurement, it’s vital that you activate and track all warranties, have serial numbers and model identifiers at the ready, and that each asset is installed and powered properly. Then, as you move into the operation and maintenance stage, issues can be overcome quickly and efficiently — with information at your fingertips that will prevent duplicate service calls and costly ignorance of the asset’s warranty eligibility.

By predicting when an asset will reach its optimal peak performance and leaning into that window, you can calculate its depreciation value, ensure compliance with regulatory standards and most importantly, keep your business up and running.

Planning a repair and replacement budget

Unfortunately, breakdowns are every bit as unavoidable as death and taxes. At that point, a key question presents itself: Is it worthwhile to repair the asset? Or is it time for disposal and replacement?

This is one moment where, if you have good asset management software to back you up, you’ll be empowered to turn a crucial decision into an educated one. For starters, every breakdown is a learning opportunity. A CMMS platform should compile and analyze them, across all your locations, so you can answer questions like: What’s my most commonly-occurring problem? What’s my most expensive problem? Is one manufacturer brand outperforming another?

If you have Ecotrak as your facilities management software solution, it’s simply a matter of any authorized person in your company taking out their phone, opening the app and looking under Ecotrak’s proprietary “Decision Making Tool,” designed by restaurant and finance veterans with such a moment in mind. The tool displays personalized details about your asset, its original value and likely cost of a replacement. It also offers an estimated useful window of service (based on the hive-mind experiences of other users) and reminds you where yours is in that likely lifespan.

The “Decision Making Tool" or DMT — whose icon is a weight-balance scale, to underscore the plus/minus decision being weighed — then gives you a likely estimate for your repair, shows you how much you’ve spent already over the lifetime of the appliance, and offers an easy-to-read gauge system to make the choice even more transparent. If the needle is in the red, it’s likely time to replace; if you’re in the green, a repair is the more reasonable choice. But perhaps most helpful is the small yellow section, indicating that while you’re safe for now, it would be wise to begin setting aside funds for a replacement in the near future.

Facility management dependence

Whether you have dozens of locations, or simply dream of getting there someday, it is crucial that you monitor the lifecycles of your assets.

Ecotrak maintains information specific to the asset, then makes it available to both the customer and the service provider, enabling a smoother interaction. From manufacturer to model to serial number, to the ability to track warranties on three different levels (manufacturer, service provider and the often-overlooked component warranties), to documentation and saved photos of the actual equipment, everything is available on the app with a few swipes of a finger.

Another great tool is the custom flagging feature. Imagine if you or your management team could run a report for a designation such as “earmarked for replacement,” immediately pulling up every asset in your company approaching that final stage of the lifecycle. Keep in mind, this is real time information, provided up-to-the-minute by those you have designated at various locations. If a manager came in to find a broken dishwasher during the morning shift today, that could be on your report. This flag feature allows you to build your budget, anticipate work to come, and increase visibility and communication — and keep in mind, you can make as many flags as you need for subheadings like “inspection needed,” “ready to be cleaned” and more.

All this asset lifecycle information, of course, informs your company’s facility management efforts, and vice versa. With a company like Ecotrak, it’s all under one convenient umbrella, constantly updating data that you can view, adjust and share from your mobile device or desktop. So, if you want to see the problems costing the most money across your company, or the ones occurring most frequently, you can do so with precision; if you’d like to view your company’s spend by asset (who knew that maintaining the soft serve machine and grease trap costs as much as the HVAC?), or monitor which vendors are taking the most average days to complete a work order, all that information is similarly up-to-the-minute and ready for a deep-dive analysis.

The bottom line

When it comes to asset lifecycle management, you can either be driving the train or, if you’re not careful, get run over by it. Imagine all the considerations listed above, multiplied by a dozen locations — or a hundred, or a thousand. Whether you’re talking about Del Taco managing 300 corporate locations with their Ecotrak software, or other existing partners like Outback, Burger King and Lazy Dog, it’s easy to see why a software solution for overseeing your assets is a no-brainer.

INDUSTRY INSIGHT

What's Happening at Ecotrak

When you joined the restaurant industry, you wanted to nourish people’s hearts, souls and stomachs. You likely dreamed of helping create a gathering place where co-workers could get together for a happy hour, families could celebrate a birthday, or friends could catch up over appetizers. The last thing you wanted to deal with was work orders, broken equipment and invoicing. Which is where facility management software comes into focus.

A competent software solution provides invaluable infrastructure to a business, allowing many daily headaches to be eased by a streamlined, proven system; a poor choice, however, could just compound those headaches. With that in mind, let’s take a look at what facility management software is, and how it can help you get back to the things you really care about.

Facility management software also called a computerized maintenance management system (CMMS) is a software that maintains a database of information about an organization’s assets, repair and maintenance operations. Businesses can place services requests, manage workorders, communicate with vendors and analyze data from a dashboard, thus helping facilities managers (FMs) do their jobs more effectively.

The benefits of good facility management software can be broken down into three categories. In some ways, each feed off the other; in a perfect world, they serve your business like a good insurance policy — operating quietly in the background, while giving you piece of mind.

1. Data analysis

Robust, customizable reporting empowers you to make more educated business decisions. Viewing your spend data by such variables as equipment type, location and manufacturer affords greater insight into what’s costing you money and why.

Years ago, such data was mostly anecdotal, and most analysis had to be based on gut feelings. The more locations your restaurant opened, the more difficult it became to spot trends, know which equipment was giving you the best bang for your buck, and adjust plans accordingly. Today, if you properly track your facility management issues, it’s so much more than simply getting a grill fixed.

Every time a new piece of equipment enters one of your locations, you take a few moments to share information about its make, model, purchase date, warranty and other such details. A good facility management system will take it from there — no matter how big you get, no matter how much equipment you need to track.

When equipment breaks, rather than picking up the phone, texting, emailing or searching online for who to call, you simply place your request through a solution like Ecotrak; information is extrapolated from your original registration, a work order is created, and you get updated every step of the way as the equipment is repaired — even allowing the service provider to invoice you, and integrating with your own accounting software if you so choose.

When you have your spending monitored and your profit & loss performance maximized, that eliminates guess work and allows you to manage your operations much more effectively. It also empowers you on the fly to ask and answer questions like:

“What’s my most expensive problem?”

“Is one manufacturer brand doing better than another?”

“Is there a model within that brand that might be outperforming another model?”

A good facility management solution will provide immediate answers to these and other questions in easy-to-understand, highly-interactive graphs and models that bring you the next-level facility management data and analytics a growing business requires. By staying ahead of your asset’s needs, you can maximize its lifespan and minimize energy consumption — both important factors in sustainability. A good facility management solution also automates industry, state and federal regulations that require documentation of work and compliance.

Imagine having such information at your fingertips, and how it could assist you in making educated, data-driven decisions for your business.

2. Increasing Efficiency

If you aren’t actively tracking your refrigerant use and considering ways to redirect spending towards greener products, you aren’t doing your best to reduce carbon emissions, provide a healthy and clean environment for customers and employees, and save money on energy costs and compliance. If your aren’t budgeting for futures breakdowns and replacements based on past breakdowns and replacements, you aren’t properly budgeting and anticipating work to come.

Good facility management software gives you a wider overview. The ability to manage vendors, receive proposals, request service, handle invoices or approve work orders should be at your fingertips, using cutting-edge technologies and easy-to-navigate mobile apps designed with the operator in mind. A good facility management solution will give you this information in real time, allowing you to instantly see the status of every work order and the service history of every product, as well as its cost.

Typically, it also empowers those around you, allowing you to focus your time and energy elsewhere. If a manager at a location in another state comes in tomorrow morning to find a misbehaving refrigerator, as long as they are authorized, proper servicing is at their fingertips. When they submit a service request, you can set yourself and others up for approvals — and redundant requests are rooted out, eliminating the cost of mistaken visits from double-booked service providers. So when the next manager comes in for the night shift and encounters the same problematic refrigerator, their service request would result in an alert that the problem is already being addressed.

A system like Ecotrak — designed by people with a long history the restaurant and hospitality industry— provides an app that allows the user to execute such service requests in moments, as well as approving work orders and invoices with a swipe of the finger. It’s also a communication tool, enabling not only messages with service providers, but also a reviewable record of such communications. The app’s clear interface empowers the user by displaying the estimated life of equipment, its current age, and spend vs. replacement costs.

It takes about 30 seconds to find your restaurant location, select your problematic piece of equipment, type what’s wrong and if you’d like, upload pictures. At that point, you hit “submit” and can go back to work, knowing the ball is rolling.

3. Saving money

On average, Ecotrak users find that warranty, call aversion and troubleshooting savings result in a 5 percent reduction in maintenance spending, one that typically has the software paying for itself in about six months.

Working with such industry-leading brands as Applebee’s, Fresh Brothers, Lazy Dog, Burger King and Buffalo Wild Wings, Ecotrak facility management software is constantly updated with cutting-edge industry advancements and insights, bringing users the latest ways to track their spending. Some have a handful of locations and big plans to grow; others use Ecotrak across thousands of locations.

Taking a unique, asset-first approach, Ecotrak tracks all things related to facilities and assets, giving you a snapshot of not only what you’re spending but where the money is going, what it’s being spent on and with which vendors. This results in a starting point to drive cost-saving initiatives and cost-reduction initiatives while gaining valuable insight.

There are 3 ways the company saves its restaurant operators money: Tracking warranties (and making that information available to both the operator and the service provider), spotting duplicate service requests (eliminating redundant service call charges), and troubleshooting. On average, Ecotrak customers save 5 percent on their repair and maintenance spend, empowered by AI-driven technology that allows them to manage spending, improve capital planning and better forecast the future.

The Ecotrak desktop interface has the same functionality as the mobile app, but adds in summary information and increased settings flexibility. All told, information is power, and a good facility management solution empowers you with granular data, viewed in a wide, flexible array of options.

INDUSTRY INSIGHT

What's Happening at Ecotrak

Image Credit: Mendocino Farms Sandwich Market

Mendocino Farms opened its first cloud kitchen in Long Beach, California in November 2020. We caught up with Gene Davis, CRFP, Senior Director of Facilities, to talk facility management technology, cloud kitchens and how the brand fared during the pandemic.

Mendocino Farms recently implemented Ecotrak Facility Management Software. Why did you go with Ecotrak?

We were with ServiceChannel, and we switched to Ecotrak. I've spent a lot of time with ServiceChannel. I rolled out ServiceChannel in my last two companies, and Mendocino Farms already had ServiceChannel. I knew about Ecotrak, and after seeing their demos, I decided to switch. ServiceChannel served us well, but Ecotrak is more intuitive, easier to use, has more analytical tools, and for our younger managers, it's mobile-based and just a cooler technology. The other reason is the price. ServiceChannel and Ecotrak offer similar features, but ServiceChannel tacks them onto the price. Everything was a la carte. With Ecotrak, we get one price and all the features, and that was appealing to us.

How has your customer experience been with Ecotrak?

I've received great service during the transition. With ServiceChannel, if you have a problem, there's a help desk. You submit an email and it goes back and forth. Ecotrak has amazing support. They have somebody manning the phone 24/7. If I have a question, I like to pick up the phone and talk to somebody versus typing a message like a service request and then waiting for an email response. I’m in California; my stores are in California, and Ecotrak is based in California. I'm excited about having a better support system. That was a big factor.

How is the transition going?

It’s good. We have a client success person, Michael, who is great. It was easier than I thought it would be. The salesperson said, "This is going to be really easy." And I said, “Okay, great,” but I was skeptical. Nothing is easy, especially in facilities. Anything that can go wrong will go wrong. But we've had weekly calls. They've done a lion's share of the dirty work: the loading of assets and PMs. We're about to start the final phase: training. They have a great trainer and training program.

How have your restaurants fared during the pandemic?

Our brand is delivery heavy. That’s one of the reasons we've done so well during the pandemic. The brands that had drive-through and delivery in place made it through.

The company opened its first ghost kitchen. Why don’t you call it a ghost kitchen?

People call them ghost kitchens or virtual kitchens, but we say cloud kitchens. “Ghost” sounds like there's nobody there, but there are lots of people at our cloud kitchen.

Did Mendocino have a cloud kitchen before the pandemic?

No, we opened one in the middle of the pandemic. At the time, opening restaurants was difficult. It was easier to open a cloud kitchen. It shares a facility with 12 or 13 other concepts.

What challenges did you face with opening the cloud kitchen?

Two ways. They can use popular food-delivery apps, such as Grub Hub, Uber Eats, Postmates or Door Dash – we partner with all of them – or use the Mendocino Farms app. Customers can also pick up their orders. The facility has food lockers. A staff member tells them their locker number. It’s contactless since they paid on the app. On our website, it's promoted as “Long Beach Kitchen – Delivery and Pickup Only” to make that clear for guests so they don't get dressed up and show up for dinner at that location.

Does the cloud kitchen support catering?

Yes. Pre-pandemic, catering was an enormous part of Mendocino Farms’ business. We were known for our catering. So, we hope, as people go back to the office, and things slowly go back to whatever the new normal is, that we will be catering a lot more out of Long Beach.

Are there more cloud kitchens in Mendocino Farms’ future?

We've had great success with the first one. Sales are great. The Operation is great. So, we're looking at a couple of different sites – one by Berkeley and one in San Francisco. The small footprint makes it easier to add more to our portfolio. We're convinced that adding more kitchens will strengthen our brand.

What trends have you noticed?

Consumer behaviors have transitioned to online ordering. People like having their groceries delivered because of the convenience. This translates to cloud kitchens well. People will continue ordering food online for delivery or pickup. People get into a routine and it becomes the norm. People are used to it. They're comfortable with it, and they like the new way better in some cases.

Gene Davis , CRFP, is the Senior Director of Facilities at Mendocino Farms Sandwich Market.

INDUSTRY INSIGHT

What's Happening at Ecotrak

Facilities management undergoes constant change and innovation. Everything including work order organization, asset and warranty management, technology interfacing and even the very labor force itself is rapidly evolving. In such a fast-paced industry it’s imperative that professionals reach for the most optimal tools.

In a recent survey conducted by Connex, the leading retail and multi-site Facilities Management Network, 83% of respondents said it is time to change what we call a CMMS. CEOs across the industry agree that term is antiquated and does not communicate what today’s technology systems truly do. Is a computerized maintenance management system (CMMS), which first appeared in 1965, the best title for a tool that aids us in so much more than automated maintenance management?

Focus on the Future

Facility professionals have largely flocked to CMMS because of its automation. The term emphasizes technology. Today, the emphasis is on people and serving their needs. We’re surrounded by computers – our cars, phones, gadgets, kitchen appliances all have computers in them. Saying something is “computerized” sounds dated. Still, these systems are the hub for operators, dispatchers, techs and all levels of maintenance support. However, it is more than just keeping a well-oiled machine humming. It is more than submitting work orders and relying on technology to automate the next steps. These systems help us improve communication and relationships between teams and vendors. They empower our teams to work more efficiently and offer visibility and transparency into the business. Their use cases ripple into all areas of the business, taking maintenance management to the next level.

Artificial Intelligence or AI and its predictive abilities are around the corner. Augmented reality certainly has a role in the future of facility management. Imagine designing, servicing and managing spaces without being physically present. To prepare for the future, we need the right resources, the right people at the helm and a more accurate term for these systems.

Time to Redefine

The term CMMS once hit us as cutting-edge but has since dulled. It’s time for the industry to redefine it. We need a term that encompasses asset management, invoice tracking, project management, business intelligence reporting and analytics, equipment history, and more. We demand so much more from our systems than work order organization and maintenance management.

CMMS technology is steadfast, but the terminology is dated. We have grown out of the term like a pair of old work boots. The technology is poised to tackle new jobs. Whether it is called LCAM (Life Cycle Asset Management), EAM (enterprise asset management), APM (asset performance management), IWMS (integrated workplace management system), IFMS (integrated facility management system), FISH (facilities integrated service hub) or any other combination of the alphabet, a CMMS by any other name would smell just as sweet.

Source: ConnexFM

Mike Snyder is the Founder and Chief Operating Officer of Ecotrak.